- 983191003073+

- 989022720020+

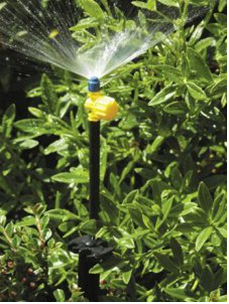

Sprayer and its types

What is a sprayer and what is its use?

A poison is a substance that has a plant origin and penetrates a certain amount inside the tissues of the body, causing the human body or any other living organism to stop functioning. A poison sprayer is a device that sprays these chemicals in order to speed up the poison spraying operation, save money and spread the poison better in the desired place. Currently, about 30 to 50 percent of the poisons consumed in the country are wasted due to improper use of sprayers.

– General principles of spraying

Pesticides may be used in several ways. It is presented in an almost pure form, which is technically known, and with a solvent, which is usually water, as an emulsion. It is used in two ways: dusting and granulation. These toxins, in a spraying program, must be uniformly applied to the plant. (or other intended targets) be sprayed. The most suitable device for breaking the solution and turning it into a toxic drop is a sprayer. The main components of a sprayer, depending on its type, usually include: tank, pipes, connections, pumps, turbines for generating strong air flow, electric motors, nozzles. It’s filters and canvases. What is more important in the production of toxic drops is paying attention to the characteristics of the drop. Specifications that should be suitable for the desired goals in spraying, such as; The evaluation of the diameter of the drops, the number of drops per unit area and also the distribution of the image below shows well that paying attention to the mentioned specifications and the relationship between the diameter and its number, according to the intended purpose, can increase the efficiency of the spraying operation. to give

The size of the diameter of toxic droplets is calculated in terms of “micron”. For this purpose, cards sensitive to water or oil are used. In this way, when working, a number of these cards are placed under the sprayer at certain and multiple intervals. After the appearance of small and blue spots, using a special device (Optomax) or comparing with index cards, the three mentioned characteristics include; They evaluate the diameter, number and distribution of drops. In this way, the spraying techniques are modified according to the target.

– The types of sprayers are:

. Manual back sprayers

A variety of small sprayers that are widely used. The components of these sprays usually include:

1- Reservoir

2- Special base for placing on the ground

3- Suitable support for placing it on the back of the sprayer worker (just like a backpack).

4- Manual pump that works by moving a special lever.

5- Chamber under pressure

6- Lance, which is equipped with an on/off valve with a trigger valve, and one or more nozzles are installed on it.

In order to use these devices better, it should be completely attached to the back, and if it is loose, the related straps should be adjusted so that it stays in place when pumping and moving, so that the worker can work more easily during spraying. Some types of these sprayers are not completely filled so that the remaining space is used to pressurize the air and use it as a back sprayer with continuous pressure.

. Sprayers behind the tractor

They are usually installed on the three connection points of the tractor and their structure consists of a tank, pump, control valves, strainers, stirrer, canvas, nozzles and connecting pipes. Each of these parts has different types. The provision of a long canvas makes it possible to increase the width of the spraying band and reduce the number of tractor laps across the fields. Of course, in general, the length of the canvas is fixed for farmers in spraying.

– Classification of sprayers according to the type of use

Sprayers are usually used on agricultural and garden crops based on the type of application. Therefore, the common sprayers in Iran can be divided into agricultural and garden as follows:

A: Agricultural sprayers:

Back atomizer sprayer – Back micron sprayer – Canvas tractor back sprayer – Agricultural turbine sprayer

B: Garden sprayers:

simple back pump sprayer – manual back lever sprayer – lance motor back sprayer

Farguni sprayer – spring sprayer – garden turbine sprayer

Back atomizer sprayer: The technique of this sprayer is to break the solution and produce a toxic drop, using a strong flow of air. This operation is done through a simple turbine installed on the central axis of a two-stroke engine. In addition, the spraying direction can be controlled by the cap or different nets placed at the end of the hose pipe. The tank capacity of this sprayer is about 15 to 25 liters. It is specially designed for field spraying. Although due to the relatively large difference between the droplet diameters of this sprayer, it has been evaluated as poor in terms of spraying quality, but by installing a microner or electrostatic head on it, in addition to improving the quality, its efficiency increases significantly. Its use is only for spraying insecticides or fungicides and it should not be used for spraying herbicides. At the same time, this sprayer has the capability of dusting, granulating and flame thrower.

Back microner sprayer: The technique of this sprayer is to use centrifugal force to break the solution and produce toxic droplets in such a way that; The toxic solution inside a bowl or a rotating cylinder (which is placed at the end of the axis of an electric motor rotating at a high speed) is distributed around in the form of uniform and homogeneous drops. Currently, as new generation sprayers, It has the best spraying quality and the expected properties of toxic drops. But in terms of efficiency, it still cannot compete with air spraying or turbine sprayers. Unless, in the future, such sprayers will also be equipped with microner caps.

Simple pump sprayer (hand sprayer): In general, sprayers whose output is supplied through hoses and lances are used in gardens. A simple pump sprayer is also one of these sprayers. Its tank is a metal cylinder with a volume of 10 to 25 liters and usually made of galvanized material or compressed plastic, which makes its two sides convex in order to withstand the pressure of the stored air. The technique of this sprayer is to use pressurized solution to produce droplets. In this way, it is placed on the user’s shoulder through a simple manual pump after the tank pressure reaches the maximum allowed. With gradual discharge, the toxic solution comes out from the nozzle of the spray cone in the form of toxic droplets. For this reason, at the beginning of the work, the drops are smaller and at the end of the work, the drops are larger. This sprayer is only suitable for use on a few trees or shrubs and should not be used for weed control.

Back lever book sprayer: The technique of this sprayer is solution under pressure. with the difference that the necessary pressure is not stored in the tank, but at the same time as pumping, this pressure is provided behind the nozzle. Also, the fluctuation caused by pumping is also prevented by the pressure chamber that is built in the vicinity of the tank. The main advantage of this sprayer compared to the back pump sprayer is its constant pressure during spraying. Using this feature, it can be equipped with a boom and T-jet nozzles to be used in the fight against weeds.

Back sprayer with a lance motor: This complete sprayer is the same as a lever book sprayer. with the difference that the necessary pressure is provided by a two-stroke engine instead of a lever. From a technical point of view, it is considered one of the pressurized solution sprayers. Its tank volume is 20 to 25 liters. Its lance and lance head have the ability to change the spraying angle and the diameter of the drops. Also, due to the stability of the pressure, it can be equipped with a canvas and a nozzle to be used on crops.

Farghuni sprayer: 100 liters: This sprayer is designed for spraying gardens. Because of its tank capacity, it is known as the 100-liter Farguni sprayer. It has a four-stroke engine and piston pump in order to provide proper spraying pressure. It can be serviced through two outlet valves with a range of 25 meters through a hose and a lance. The use of this sprayer, due to its technical disadvantages, is not suitable for fields and crops. Of course, if necessary, it can be changed to spraying fields by installing a two- or four-meter canvas from Ser Lance. But the quality of spraying will not be as good as the performance of specialized agricultural sprayers.

Zhanbei sprayer: This sprayer, similar to Farguni sprayer, is designed only for gardens. with the difference that it does not have fixed wheels and tanks. So that in addition to changing the volume of the tank, suction hoses can be temporarily placed inside any tank. In order to create a greater range, in terms of the length of the output hoses and to provide the appropriate pressure in the antenna lances (including spraying of trees), by installing a stronger motor and pump on it, this goal will also be achieved. Its calibration is similar to Farghuni sprayer.

Sprayer on the back of a canvas tractor: This sprayer is designed only for spraying fields. In our country, it is usually made with a 400-liter tank and an 8-meter canvas. Since most fields are leveled without using a camera and appropriate technology, it is usually uneven and the length of the canvas cannot be increased to more than 8 meters. Because accurate calibration of the sprayer is impossible. Of course, in other countries, 40-meter canvases are also used for large and flat fields. In addition, by changing the pump, which is usually a diaphragm type, and replacing it with a piston pump, if necessary, it can be used as a spring sprayer for spraying gardens by installing a hose and a lance. Dar is used in the following ways:

1- Mounted sprayer: it is completely dependent on the tractor and needs the connection of three points of the tractor, including the shaft and two hydraulic arms.

2- Stretch sprayer: In such a way that it is semi-dependent on the tractor. To supply the energy of the pump, only from the shaft. uses By installing the sprayer on a chassis with two wheels, there is no need to use hydraulic arms.

3- Self-propelled sprayer: In such a way that it is completely independent and does not need any other agricultural machines.

What is calibration?

In general, calibration in crops is determining the amount of solution consumed in one hectare, taking into account the expected properties of toxic droplets. In order to achieve this goal, three main variable factors should be controlled in agricultural machine sprayers, either behind a canvas tractor or an agricultural turbine, according to the goals of spraying:

Spraying pressure – flow rate and nozzle selection – speed

Since this type of calibration needs to perform operations, evaluate the condition of the sprayer, as well as accurate expert calculations, it is not possible to provide a general pattern. Rather, such sprayers must be adjusted and calibrated for each field, in the time and place conditions of the same field. Therefore, before spraying, it is necessary to refer to plant protection experts, agricultural promoters, private medical plant clinics or licensed plant pest control companies in the field of service centers and carry out the operational calibration of the desired sprayer from them. be requested The most important indicators of the evaluation of the sprayer behind the canvas tractor, before use, the number of all nozzles should be the same in terms of flow rate and spraying angle, and the gap of the nozzles should be along the canvas. Also, there should be a 50-mesh strainer behind them, and the strainers on the door and under the tank should also be controlled. Using a graduated container or a one-liter measuring cup, measure the flow rate of the nozzle in one minute and match it with its number. The distance between the nozzles on the canvas should be adjusted to the sprayer’s certificate, which is usually fixed at 50 cm in Iranian sprayers. It is mandatory to have a drip stop (check valve) behind the nozzle. Ensure the health of the shock absorber spring on the canvas. all the connections, from under the tank to the regulator, split valves and pipes for transferring the solution to the nozzle, as well as the return pipe to the tank, should be controlled so that there is no leakage and the solution passes through them completely. From the health of the regulator and adjustment screw Make sure to pressurize. According to the number of the nozzle, the height of the canvas should be controlled from the product – in order to comply with the overlapping principles.

Map

[neshan-map id=”1″]

Address

Isfahan, Golpaygan, Ayatollah Mahmoudi Blvd., in front of Laleh Park, Fanab Sanat Golpa Company

About Company

Fenab Sanat company produces all kinds of wood chipping machines and agricultural tools, which are sold in different models. It also has several patents and is one of the largest producers and exporters of agricultural tools in Iran.